What is the hit-and-miss engine?

A hit-and-miss engine is a type of four-stroke internal combustion engine that was popular from the late 19th century through the 1940s. It operates at a set speed controlled by a governor. The engine got its name from the way it operates: it "hits" or fires only when running at or below the set speed, and "misses" or doesn't fire when running above the set speed. This speed control mechanism differentiates it from throttle-governed engines.

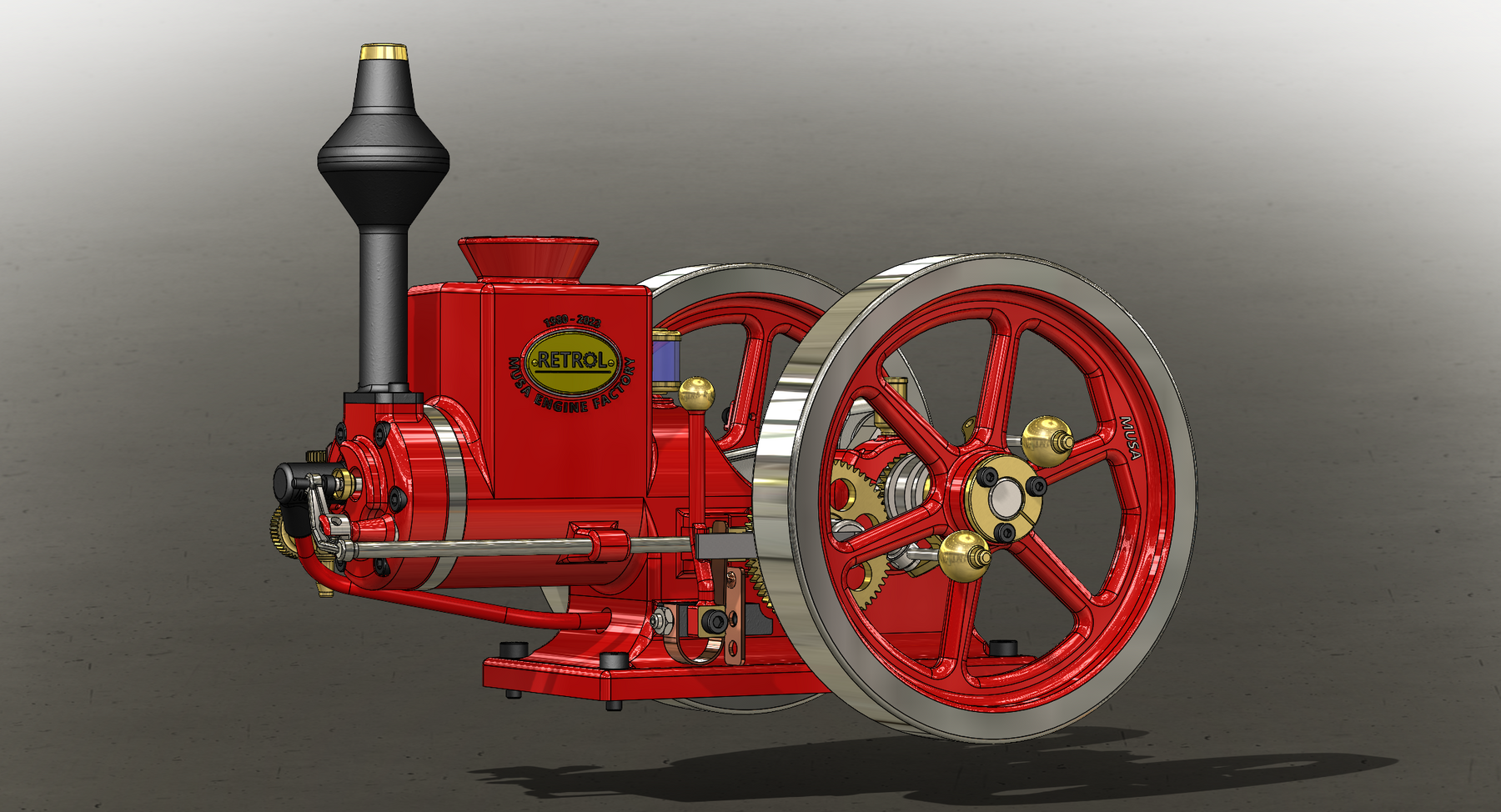

Hit-and-miss engines are flywheel engines, meaning they have a large flywheel or set of flywheels connected to the crankshaft. The flywheels store energy during the combustion stroke and release it to the mechanical load during the other three strokes of the piston. These engines were designed in an era with less advanced technology, so their parts were typically large and made of cast iron.

The fuel system of a hit-and-miss engine consists of a fuel tank, fuel line, check valve, and fuel mixer. The engine usually runs on gasoline but can be switched to cheaper fuels like kerosene or diesel. The fuel mixture is created by a mixer, which uses a needle valve attached to a weighted or spring-loaded piston. Sparks to ignite the fuel mixture are generated by a spark plug or an ignitor, which can be powered by a magneto or a battery and coil system.

Lubrication in hit-and-miss engines is primarily manual. Grease cups are used for the main crankshaft bearings and connecting rod bearings, while a drip oiler continuously feeds oil onto the piston. Other moving parts of the engine require periodic lubrication applied by the operator while the engine is running.

Hit-and-miss engines are typically of the "open crank" style, with all the engine components exposed. This design leads to a messy environment as oil and grease can be thrown from the engine. It also requires frequent cleaning to prevent excessive wear and malfunctions.

Cooling for most hit-and-miss engines is achieved through hopper cooling, where water in an open reservoir absorbs heat from the engine. Some small engines are air-cooled with the help of an incorporated fan. However, water-cooled engines are more common and often require a separate cooling water tank.

These engines were used in various applications, such as powering pumps, saws, generators, farm equipment, and cement mixers. They were particularly popular on farms, providing a labor-saving device for farmers. Hit-and-miss engines were typically belted to the devices they powered using a wide flat belt.

As more advanced engines emerged in the 1930s, flywheel engines became less common due to their weight and slow speeds. Enclosed crankcase engines with self-lubrication, reliable spark plug ignition, and lighter weights gained popularity. Modern flywheel engines are still used in certain applications where low speed is desirable, primarily in oil field applications.

Many hit-and-miss engines were scrapped during World War II, but numerous enthusiasts have restored and preserved them. These engines can be seen in action at antique engine shows, steam fairs, and vintage vehicle rallies. But now, Enginediyshop will soon welcome this mini hit-and-miss engine model, so stay tuned!

Leave a comment